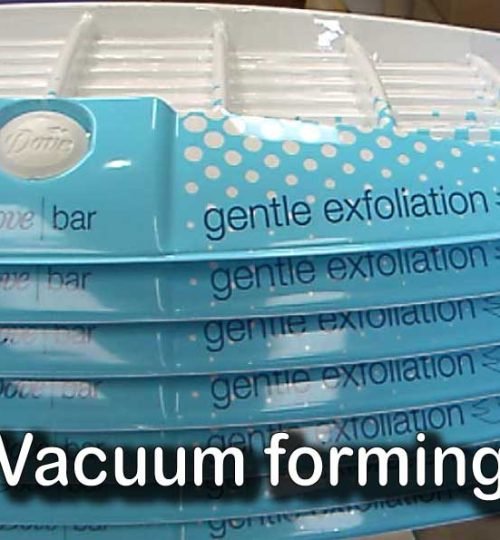

Vacuum forming

Vacuum forming

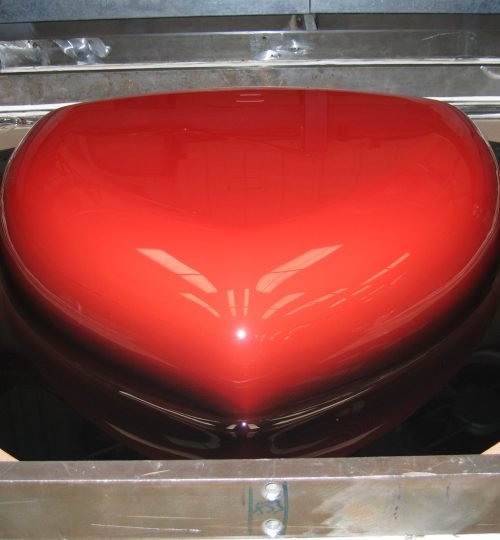

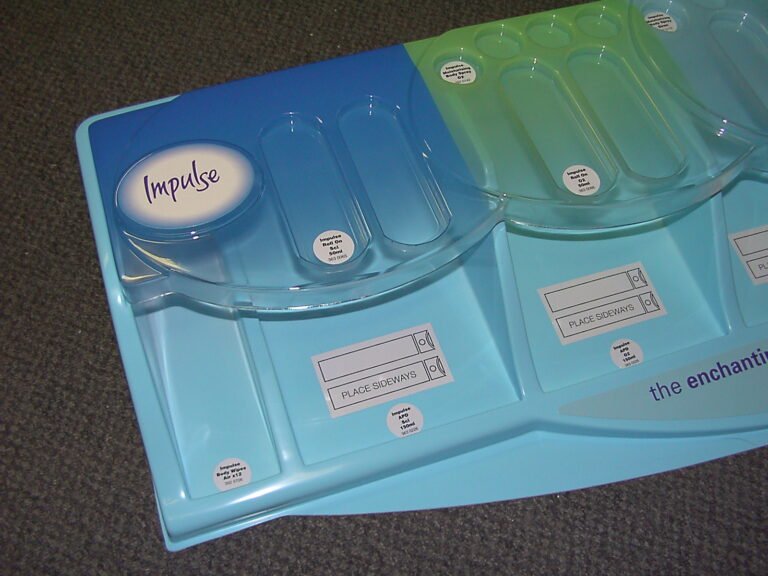

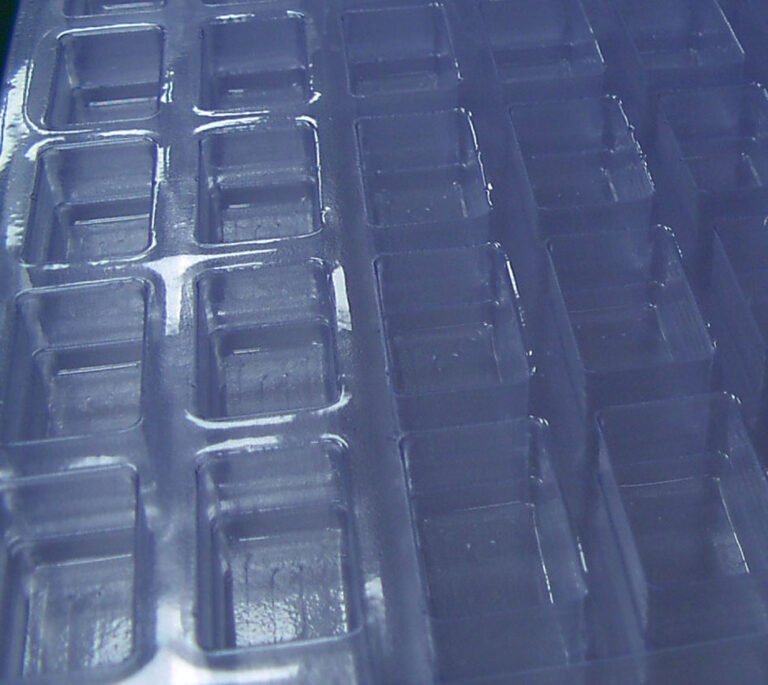

Vacuum Forming is the process of heating a sheet of plastic and forming it over a tool by applying a vacuum between the tool and the plastic.

Tooling is fixed to the bed of the machine, above this a sheet of thermoplastic is clamped into a frame. This is then heated until the plastic becomes soft and flexible. At this point the tooling is raised into the soft plastic, and the air is then sucked out from underneath the plastic using a vacuum pump. Atmospheric pressure presses down on top of the plastic sheet, which then takes the shape of the mould. This is then cooled until the plastic becomes rigid

We have 6 vacuum forming machines with a capacity to form sheets up to 2500 x 1250 mm

Secondary trimming, adding nutserts are used to complete the parts

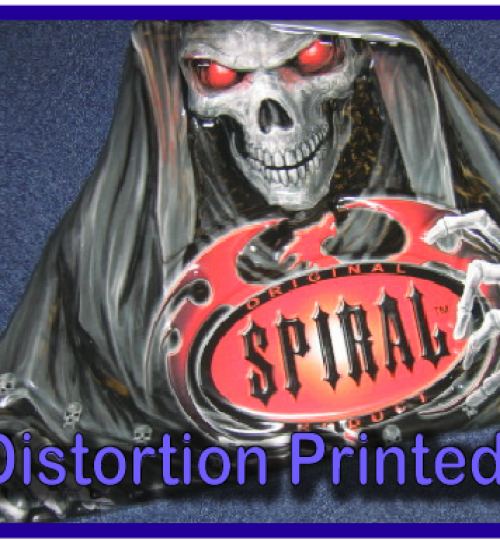

Pre-Printed Material